Written by

Vandi Collectibles

Part 1

The difference between toys and scale models is a major one. First being the scale models are made to size and are almost replicas of the original ones, with the maker taking the liberty of designing the parts as per the ease of manufacturing and aesthetics. Toys are more of attraction, durability, bright colours & functions. It focuses less on size, proportions and can also take a cartoonist approach in design to keep the children attracted to it. The process of manufacturing is more or less same but the detailing and a greater number of parts makes scale modeling a serious dedicated work for assembling and painting. To replicate the parts at a smaller scale has its own challenges in manufacturing, painting and assembling. The licensing also plays a crucial role in scale models as the model makers have to take the license from the original manufacturers to maintain the specifications and design. Listing down some of the process involved in the manufacturing of toys & scale models.

- Selecting the model: The choice of the model can be a vehicle which is very popular or has a strong fan base. The classic value or an aspirational value the vehicle holds makes it more attractive for scale model collectors. It can also be a vehicle which is too attached or nostalgic for you. Scale model is pure passion and emotion. Once the model is finalized the next step involves research.

- Research: The model which you need to create require extensive research as multiple variants of the model might be available in the market and also with various design changes as the model goes through its life cycle. You have to be particular in selecting a model and collecting the data involved like blue prints, photos, manuals, etc. The colour variant of the model is also very important.

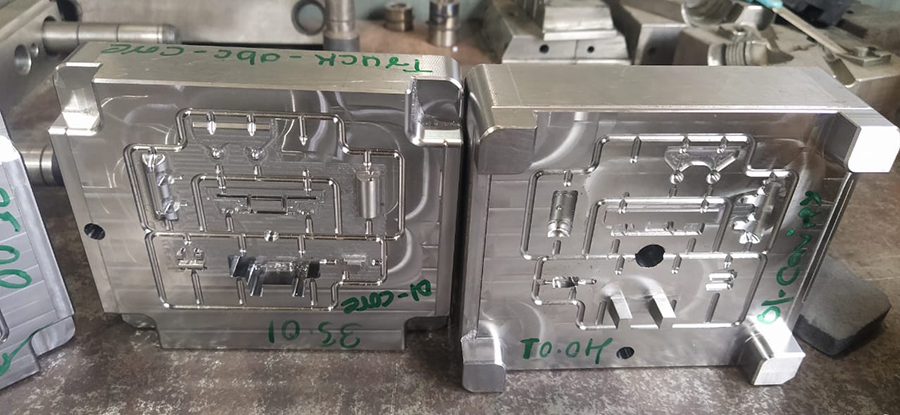

- Designing: Designing a model is a very interesting and challenging activity. The designs are prepared on the basis of the blue print dimensions or matching the dimensions from photos or parts and reverse engineering the design. The design aspect also involves the material of parts to be manufactured, the number of parts, the scale ratio of the model, the software used for designing, involvement of functions and electronics etc. The designing for scale models or toys is mostly done on the basis plastic or metal injection molding and it requires good knowledge about the part wall thickness, drafting angles, etc.

- Prototype: Once the design is completed it is essential to create a prototype so that the fitments, the touch and feel of the product could be ascertained. This was earlier done with wood or clay and would require a master craftsman to do the same. Today with the advent of 3D printing most of the parts cold be printed to check their build and fitments. The scale model is about detail so the smaller parts may require hand made parts too along with machined parts.

Will further elaborate on the manufacturing part in my next blog.

Previous Story

Hey, I think your website might be having browser compatibility issues.

When I look at your blog in Chrome, it looks fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up!

Other then that, fantastic blog!

Thanks John, will work on the same

I bought the model today and found it very well-designed and detailed. I hope you all bring many more Indian models in the future for diecast collectors like me.

slightly bigger models needed like 1:36 /1:40 /1:24 like that these 1:64 are very well detailed good job done waiting for your future products

A fascinating discussion is definitely worth comment. I believe that you ought to write

more about this topic, it may not be a taboo matter but typically people do not discuss these subjects.

To the next! Kind regards!!